Customize self-adhesive industry preferred supplier

From raw material procurement to final product delivery,our quality inspection process covers every link to ensure high-quality output throughout the supply chain.

High-Temperature Resistant Labels

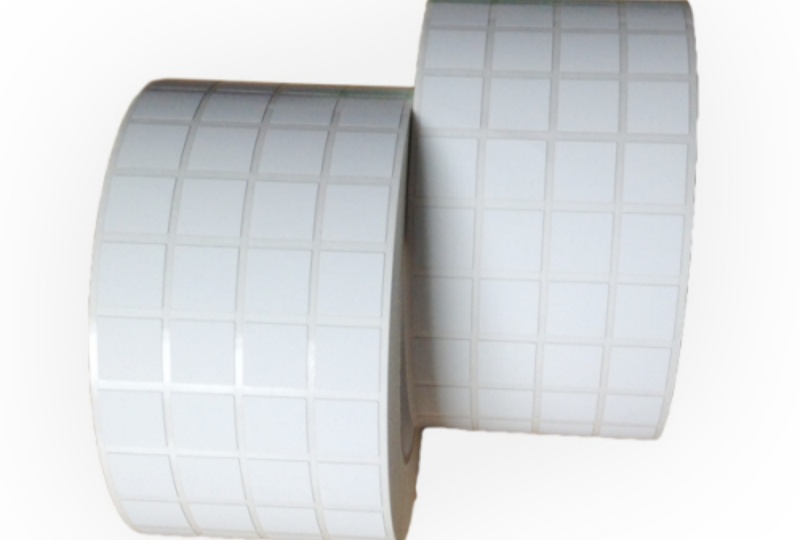

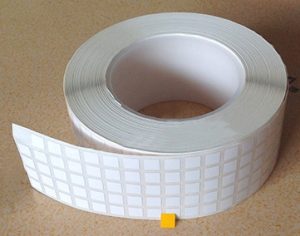

Product Name: high-temperature resistant labels

Category: Industry-specific labels – Industrial equipment labels

Material: 25μm/50μm coated polyimide (PI) film

Product Description

High-Temperature Resistant Labels Overview

High-temperature-resistant labels are specialized identification materials for extreme industrial environments, primarily used in printed circuit boards (PCBs), automotive electronics, aerospace, and other demanding sectors. The product is UL-certified, complies with EU ROHS standards, and meets international requirements for lead-free manufacturing processes.

High-Temperature Resistant Labels Structure Breakdown

1. Base Material Layer

- Material: 25μm/50μm coated polyimide (PI) film

- Key Features:

- The coating enhances surface gloss and barcode printability

- Uncoated PI films fail to meet performance requirements

- Temperature resistance range: -70°C to 375°C

2. Adhesive Layer

| Type | Temp. Resistance | Cost | Chemical Resistance | Market Share |

|---|---|---|---|---|

| Acrylic Adhesive | 200°C+ | Medium | Excellent | 90% |

| Silicone Adhesive | 260°C+ | High | Superior | Niche Applications |

| Rubber Adhesive | <100°C | Low | Poor | Obsolete |

Note: Permanent acrylic pressure-sensitive adhesive is recommended for optimal cost-performance ratio.

3. Backing Material Layer

- Options:

- Glassine release paper (economical)

- White single-coated release paper (general-purpose)

- Silicone yellow release paper (weather-resistant)

- PET release film (high-strength)

Core Performance Advantages

🔥 Extreme Environment Durability

| Test Item | Conditions | Results |

|---|---|---|

| Soldering Resistance | 260°C for 5 minutes | No delamination/deformation |

| Instant High Temp | 375°C for 6 seconds | Slight yellowing, no failure |

| Low-Temperature Storage | -70°C for 1,000 hours | No physical degradation |

| Humidity Resistance | 37°C/95% RH for 1,000 hrs | No adhesive weakening |

| UV Resistance | 1,000 hrs sunlight exposure | Stable performance (minor fading) |

⚗️ Chemical Protection

- Passes 5% salt spray test (ASTM B117, 30 days)

- Resists organic solvents, acids, and alkalis

- Complies with ASTM G26 aging test standards

High-Temperature Resistant Labels’ Industry Applications

| Sector | Typical Use Cases | Special Requirements |

|---|---|---|

| Electronics Manufacturing | SMT process/reflow soldering | Resists solder splatter |

| Automotive | Engine compartment labeling/wire harness ID | Oil/abrasion resistance |

| Aerospace | Component tracking/high-temp monitoring | Extreme thermal cycling |

| Medical Devices | Sterilization/low-temp storage | Biocompatibility certification |

| Anti-Counterfeit | Product traceability/tamper-proof labels | Thermal transfer encryption |

High-Temperature Resistant Labels’ Technical Specifications

| Parameter | Unit | Typical Value | Test Standard |

|---|---|---|---|

| PI Film Thickness | μm | 25/50 | ASTM D1000 |

| Ink Coating Thickness | μm | 25±2 | ASTM D1000 |

| Adhesive Layer Thickness | μm | 25±3 | ASTM D1000 |

| Stainless Steel Adhesion (24h) | N/100mm | 55 | ASTM D1000 |

| Epoxy Board Initial Adhesion (20min) | N/100mm | 32 | ASTM D1000 |

Recommended Solutions

🖨️ Printing Systems

- Barcode Printers:

- Zebra industrial printers

- DATA MAX-I-4310 professional series

🎨 Transfer Supplies

- Thermal Transfer Ribbons:

- RICOH B110CR (general-purpose)

- TR4036/TR4510 (chemical-resistant)

⚙️ Process Parameters

- Minimum barcode width: 6mil

- Bar width ratio: 3:1

- Print resolution: ≥300dpi