定制 不干胶行业首选供应商

从原材料采购到最终产品交付,我们的质检流程覆盖每一个环节,确保整个供应链的高质量输出.

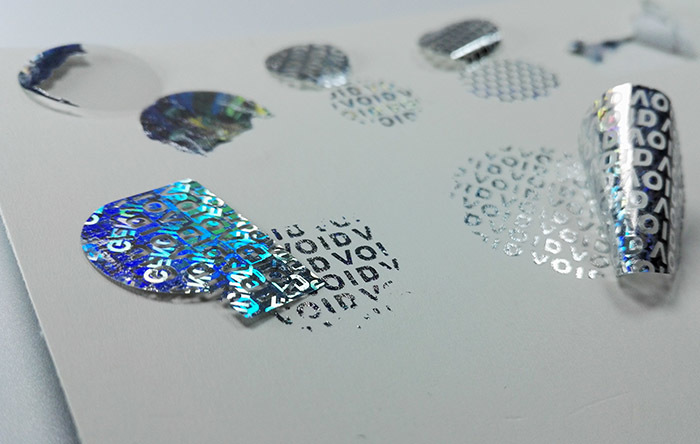

Anti-counterfeiting Label

The peel-off label with words on the bottom is also called the positive anti-counterfeiting character mold. When the anti-counterfeiting self-adhesive label is peeled off, obvious structural damage will be produced on the self-adhesive surface material. A pre-designed pattern or text (例如 “VOID”, “OPENED”, “Opened” or other patterns or text specified by the customer) will be separated on the surface of the substrate, and it cannot be restored, which plays a deterrent and warning role.

产品描述

The label with words left behind after peeling off is also called the positive anti-counterfeiting font. When the anti-counterfeiting self-adhesive label is peeled off, obvious and structural damage will occur on the self-adhesive surface material, and the pre-designed pattern or text (例如 “VOID”, “OPENED”, “Opened” or other patterns or texts specified by the customer) will be separated on the surface of the carrier, and it cannot be restored, which plays a deterrent and warning role.

Anti-counterfeiting Label Application field:

This type of anti-counterfeiting label is one of the most widely used anti-counterfeiting materials on the market and is widely used in IT, electronics, electrical appliances, medicine, 化学品, shopping malls, 后勤, aviation, express delivery, documents, letters, 仓库, and other fields. The anti-counterfeiting label is attached to the product to prevent the label from being peeled off and reused and is used to identify the phenomenon of unauthorized or illegal opening of the sealed product.

Anti-counterfeiting Label Description:

The anti-counterfeiting label series can leave white and matte silver TLB words on the surface of the attached object when removed, which cannot be cleanly removed. Thereby achieving anti-counterfeiting and eye-catching effects.

Anti-counterfeiting Label Features:

● Excellent adhesive adaptability ● Excellent anti-counterfeiting warning effect ● Compliant with ROHS directive

Constitute:

| Product No. | Substrate Material | Product Features | Thickness of substrate [um] | Color | Backing paper | Special ribbon |

|---|---|---|---|---|---|---|

| TLB3001 | 聚对苯二甲酸乙二醇酯 | VOID | 50 | White | Release Film | TLB121 |

| TLB3001A | 聚对苯二甲酸乙二醇酯 | VOID | 50 | Matt Silver | Release Film | TLB121 |

| TLB3002 | Fragile paper | Anti-counterfeit | 50 | White | White Glassine | TLB121 |

| TLB3003 | 聚对苯二甲酸乙二醇酯 | VOID | 50 | White | White Glassine | TLB121 |

Applications:

● Outdoor information, warning labels ● Machinery and equipment management, information labels

Performance:

| Property | Test Method | Typical Result | Test Conditions |

|---|---|---|---|

| Thickness | |||

| – Substrate | ASTM D1000 | 0.050 mm | – |

| – Adhesive | ASTM D1000 | 0.025 mm | – |

| – Total Thickness | ASTM D1000 | 0.075 mm | – |

| 附着力 (to Stainless Steel) | ASTM D1000 | 7.00 N/in | Speed 50mm/min, applied for 20min |

| Initial Tack | Chinese National Standard GB-4852 (J.Dow method) | ›7# | – |

| Shear Adhesion | Chinese National Standard GB/T-4851 | ›6H | – |

Anti-counterfeiting Label Adaptability Testing

Test Method: Printed using a Zebra printer with TLB121 or TLB22 ribbons. Prior to testing, samples were adhered to aluminum plates and allowed to cure for 24 hours.

| Property | Test Method | Typical Result |

|---|---|---|

| Max. Operating Temperature | 90°C for 3 days | No effect |

| Min. Operating Temperature | -20°C for 3 days | No effect |

| Humidity Resistance | 37°C, 95% RH for 3 days | No effect |

| UV Resistance | UV Sunlight™-100 for 3 days | No effect |

| Aging Resistance | ASTM G 26 (3 days in xenon arc weather meter) | No effect |

| Salt Spray Corrosion Resistance | 5% salt spray for 3 days (ASTM B 117) | No effect |

Chemical Resistance Testing

Test Method: Printed labels using a Zebra printer with TLB121 or TLB22 ribbons. Samples were adhered to aluminum plates for 24 hours before testing. Tests were conducted at room temperature. Labels were immersed in specified solvents for 10 minutes every 30 minutes (5 cycles total), followed by 10 wipes with solvent-soaked cotton after the final immersion.

| Chemical Solvent | Visual Changes | Label TLB121 | Label TLB22 |

|---|---|---|---|

| Freon® Tetramethylsilane | No effect | No effect | No effect |

| Isopropyl Alcohol | No effect | No effect | No effect |

| Inorganic Alcohol | No effect | No effect | No effect |

| JP-8 Jet Fuel | No effect | No effect | No effect |

| ASTM No. 3 Oil | No effect | No effect | No effect |

| Mil 5606 Oil | No effect | No effect | No effect |

| Skydrol®-500B-4 | No effect | No effect | No effect |

| Super Agitene® | No effect | No effect | No effect |

| BIOACT™ EC-7 Particle Metal | No effect | No effect | No effect |

| Deionized Water | No effect | No effect | No effect |

| 3% Alconox® Solution | No effect | No effect | No effect |

| 10% Sodium Hydroxide Solution | No effect | No effect | No effect |

| 10% Sulfuric Acid Solution | No effect | No effect | No effect |

笔记:

- Technical Disclaimer: The above information is for reference only. Conduct compatibility tests before application. The company shall not be liable for losses arising from operational errors or misuse. For further details, contact our Technical Service Department. Technical data is subject to periodic updates.

Shelf Life:

Unopened products can be stored for at least 1 year from the date of receipt under 23°C, 65% RH conditions.

Key Features:

- Units Standardized: Temperature (°C), 湿度 (% RH), and time units (days) aligned with international norms.

- Trademarks & Symbols: Proper use of ® and ™ symbols (e.g., Skydrol®-500B-4, BIOACT™).

- Technical Precision: ASTM standards and chemical names are retained in their original format.

- Clarity: Hierarchical structure for test conditions and results.

Let me know if you need further refinements!